ईमेल फॉर्मेट में त्रुटि भइल बा

ईमेल खाली ना हो सके

ईमेल पहिलहीं से मौजूद बा

6-20 अक्षर(केवल अक्षर प्लस नंबर)

पासवर्ड असंगत बा

ईमेल फॉर्मेट में त्रुटि भइल बा

ईमेल खाली ना हो सके

ईमेल के कवनो अस्तित्व नइखे

6-20 अक्षर(केवल अक्षर प्लस नंबर)

पासवर्ड असंगत बा

खबर

What should We Pay Attention to when Cleaning the Gravity Casting Machine?

As we all know, the requirements of gravity casting are very strict. There are certain potential safety hazards in the use of a gravity casting machine, so we will be very careful when using a gravity casting machine. But you know what? Even if the gravity casting machine is not used, the following contents should be paid attention to when cleaning the gravity casting machine.

What should we pay attention to when cleaning the gravity casting machine?

The workers cleaning the gravity casting machine should do a good job in personal protection and be familiar with various safety operation procedures. When taking castings from the stack of castings, it is necessary to take them from top to bottom to avoid the collapse of castings and injury to people. The crane should be used for the overturning of major castings. When the gravity casting machine is used, it is necessary to prevent slings or castings from pressing hands, do not overload lifting and do not hang slings on the pouring and riser of castings.

Pay attention when using the pneumatic shovel. The pneumatic shovel should be placed on the side of the casting before starting. Don't start it first and then take it to the side of the casting. When in use, do not shovel against people to avoid flying debris hurting people. When it is out of service, close the valve on the air duct and stop supplying air to the air shovel. During sand cleaning, it is necessary to prevent residual sand sticking, flashing, burr on the casting, cutting off hands by pouring and riser, and damage to eyes by flying sand.

What material is the gravity casting machine used to produce castings?

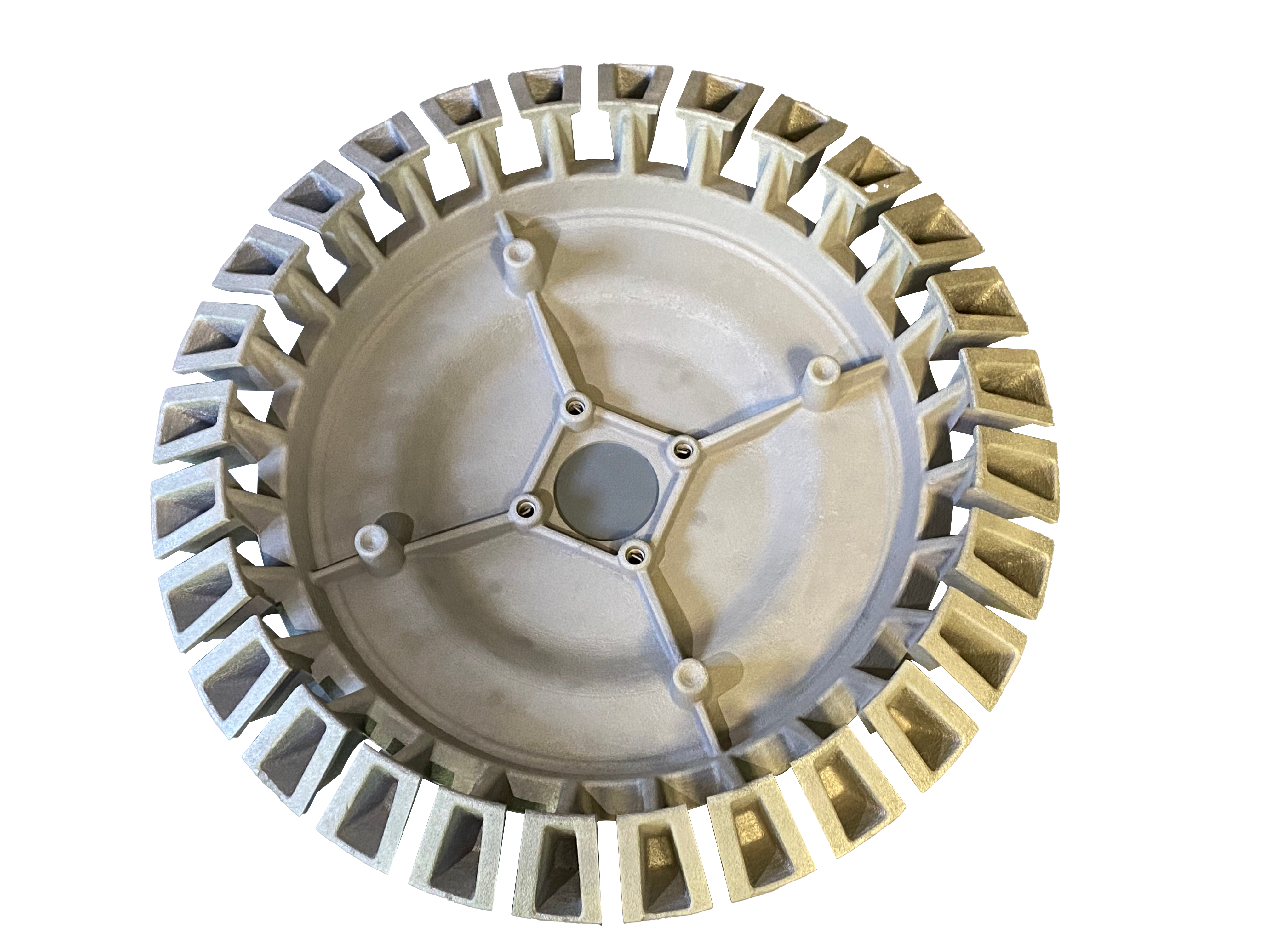

Gravity casting is widely used in the production of aluminum castings. Aluminum castings needed by many industries can be produced by gravity casting machines. A gravity casting machine can be used to produce not only aluminum castings but also other materials.

A gravity casting machine is mainly used to produce AC2A aluminum alloy materials, followed by alloy materials. However, after the casting is completed, certain post-heat treatment procedures are required to improve the mechanical properties of castings, such as tensile strength and hardness. However, alloys with different compositions have different performance requirements for castings, so the treatment methods of castings are also different.

A gravity casting machine can also be used to produce a ZA27 high aluminum zinc base alloy with an aluminum content of about 27%. This material is also more suitable for gravity casting to produce casting products, and it has good strength and toughness, low specific gravity, and a wide range of applications.

How to keep the mold temperature constant during the production of the gravity casting machine?

Because the natural cooling method takes too long and will reduce the production efficiency, the forced cooling method is used to cool the gravity casting mold. There are three cooling methods, namely, air cooling, indirect water cooling, and direct water cooling. Air cooling is blowing cooling and strengthening convection to achieve the effect of heat dissipation. The advantage of this method is that it is simple in structure and easy to make, but the effect is not good enough.

Indirect water cooling refers to placing a water jacket on the back or part of the mold for cooling, but some castings cannot be cooled violently in production, otherwise, it is easy to increase casting defects. Direct water cooling is directly passing water into the water jacket for cooling, but this method has a high cost and is only suitable for mass production. Generally, manufacturers will choose according to the application of castings.

Searching for gravity die casting machine price, tilting gravity die casting machine, gravity cast aluminum manufacturer from China, you can get high-quality products at a nice price.